CORPORATE & OFFICE PORTFOLIO

promega Corporation FEYNMAN CENTER

Fitchburg, WI

Overview

ARCHITECT

Uihlein Wilson Architects; EwingCole

Square Footage

306,000

FEYNMAN CENTER

Office Building & cGMP Facility

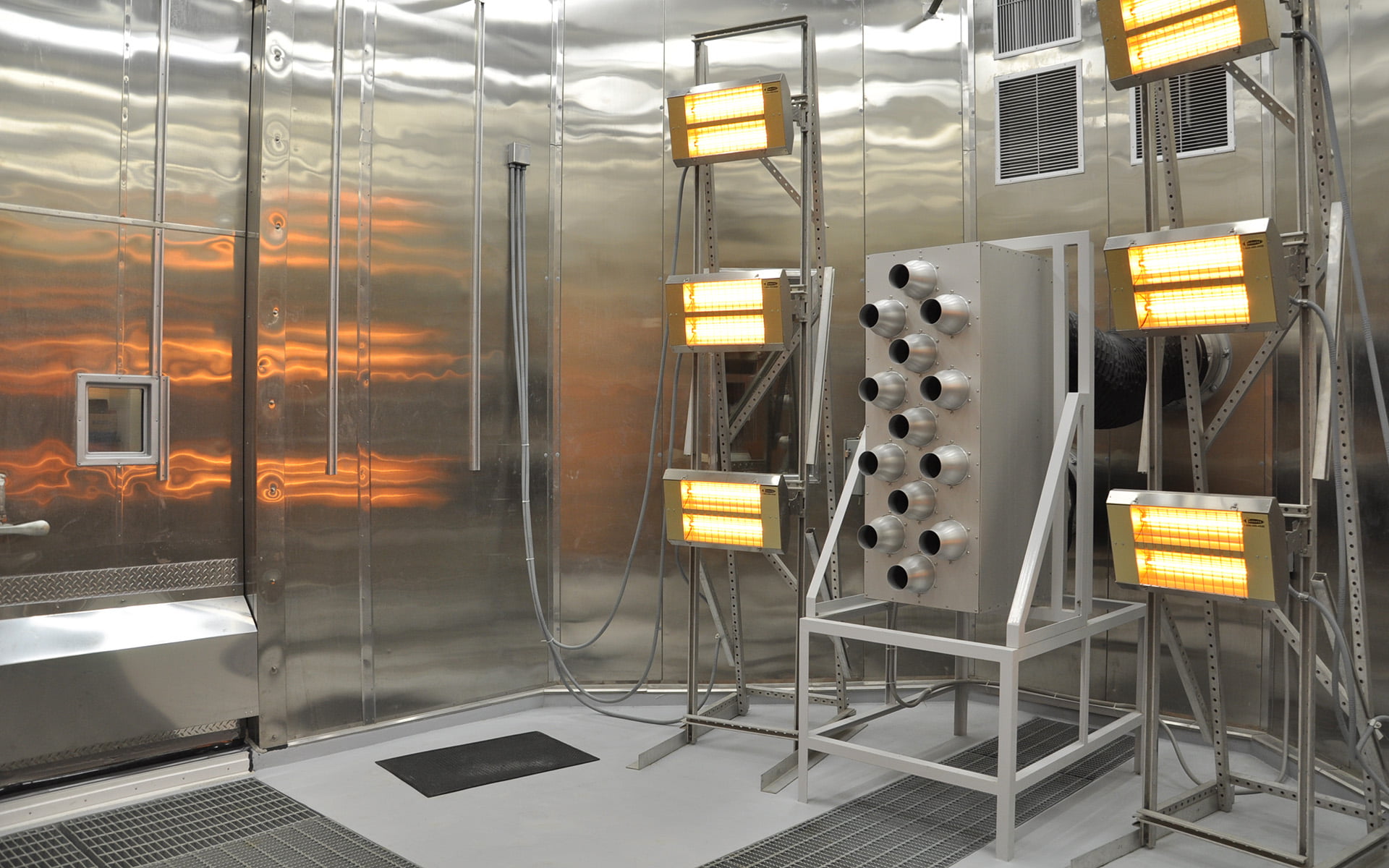

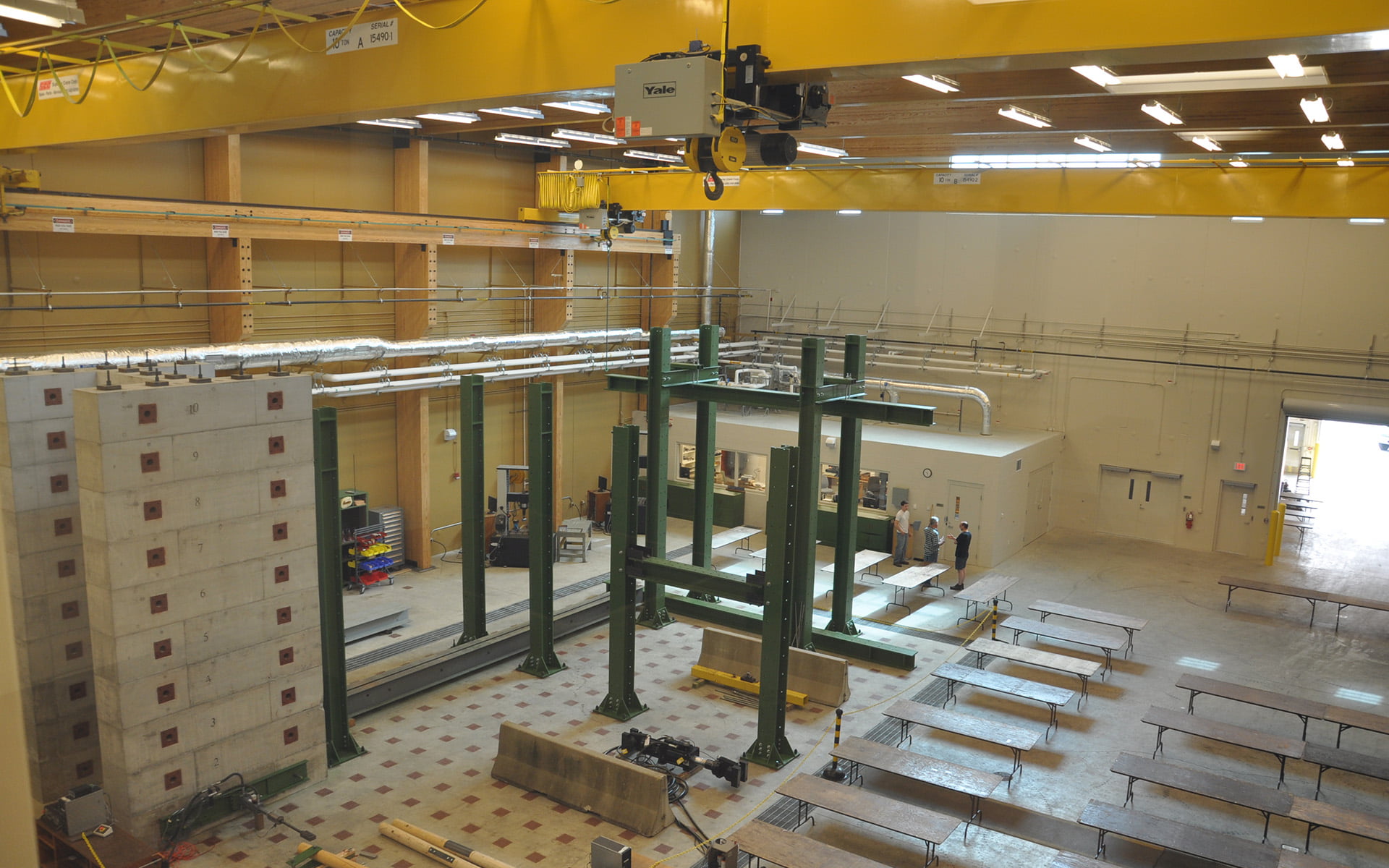

Since 1988, we’ve partnered steadily with Promega, helping them create many timeless buildings on their Fitchburg campus. Many see this new cGMP manufacturing facility as the crowning achievement of Kraemer Brothers’ 25-year relationship. Working in tandem with internationally accredited design and engineering partners, our award-winning construction crews made sure the 306,000-square-foot building and 300 car parking structure were built with exceptional devotion to detail. The mechanical, electrical and process systems are among the most sophisticated ever constructed in Wisconsin. Utilizing 63 geothermal wells and a large solar array, these sustainable energy sources heat and cool the building while also supplementing domestic hot water demand. Glulam beams, CLT panels, architectural woodwork, and a living plant wall provide an inviting atmosphere in the client center, while elaborate MEP systems power the cGMP facility. Focusing on manufacturing, quality testing, and research & development, this building offers flexibility and growth for future build-outs, remodels, and renovations. This unique facility features stunning exterior masonry and glazing systems and high quality interior finishes in this world-class architectural gem.

- 2013 ABC Projects of Distinction

- 2013 Daily Reporter Top Projects

- 2014 AGC Build Wisconsin

- 2014 AWI Award of Excellence