SCIENCE & TECHNOLOGY PORTFOLIO

Usona institute CAMPUS

Madison, WI

Overview

ARCHITECT

Ramlow/Stein Architecture + Interiors

Square Footage

107,300

USONA INSTITUTE CAMPUS

Therapeutic, Administrative, and Education Facility

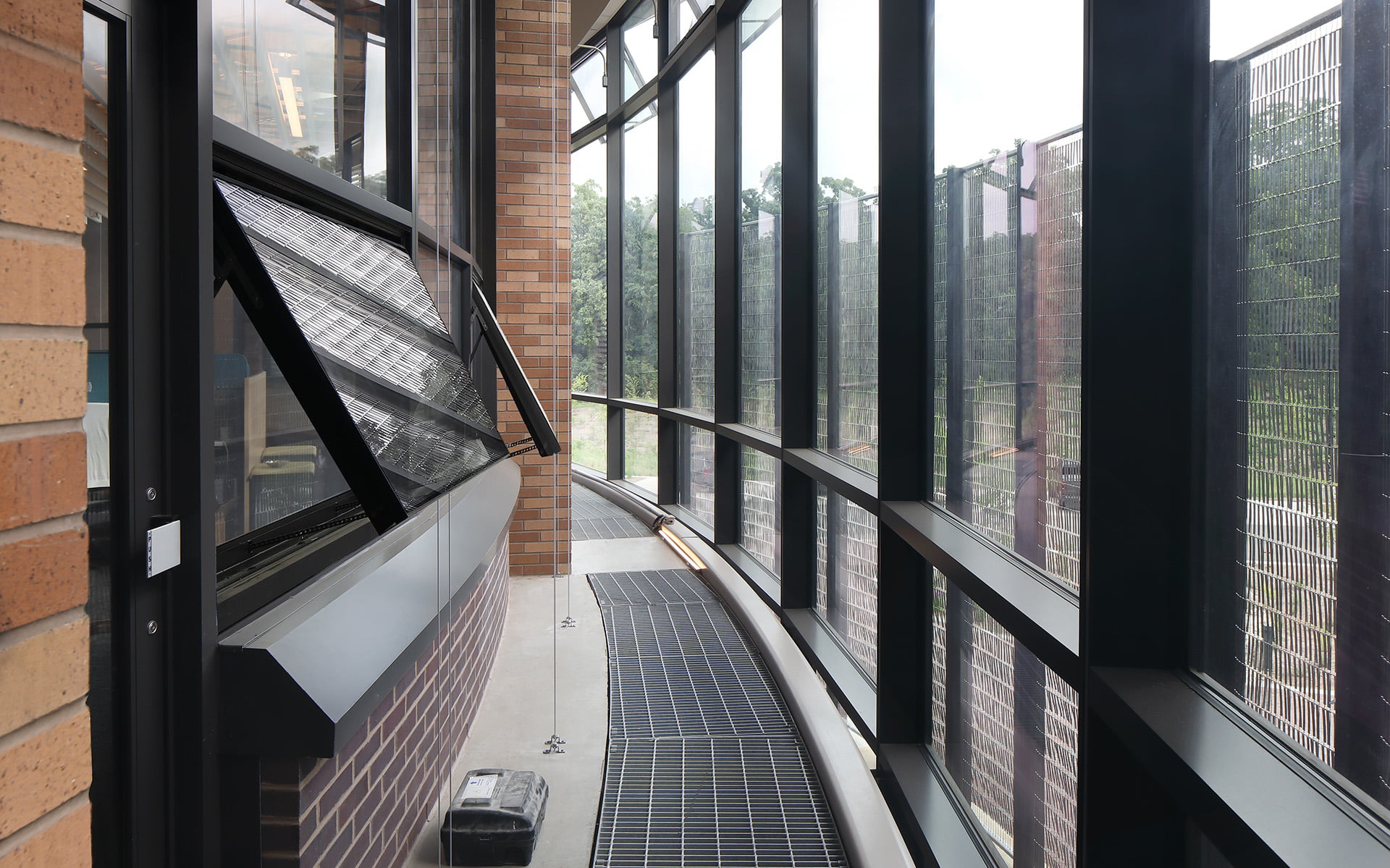

Usona Institute is a medical research organization dedicated to furthering scientific understanding and therapeutic applications of psilocybin and other consciousness expanding medicines. After being selected to construct this world-class facility, we provided valuable pre-construction input into the design. This 100,000 square foot state-of-the-art therapeutic, administrative, and education facility balances sustainability and integrative wellness practices. Designed to optimize senses by controlling light and sound, this facility includes numerous treatment rooms, illuminated therapy pods, a hydrotherapy suite, and integration rooms. Inside and out, this facility fosters a connection to nature using primarily natural materials. A beautiful combination of glulam beams, cross-laminated timber panels, wood flooring, and custom hand-crafted woodwork can be found throughout the building. At the same time, the exterior utilizes old-growth cedar siding, fieldstone and limestone masonry, wood trim, clay-slate roofing, and a copper roof drainage system. We implemented measures to preserve specific tree species and age classes while repurposing cleared trees for benches and fireplace mantles in the atrium. Other sustainable features in this remarkable facility include heat recovery chillers, geothermal heating and cooling, electric vehicle chargers, ultra-energy efficient windows, permeable pavers, and a garden roof. Expecting to attract guests from all over the world, three residences totaling 7,300 square feet are also situated on the site, providing an option for overnight stays. Varying between two and five-bedroom units, these buildings feature the same exterior as the neighboring facility.

- 2023 The Daily Reporter Top Projects

- 2024 ABC Projects of Distinction

- 2024 ABC Build on Merit

- 2024 AGC Build Wisconsin

- 2024 AGC Build Wisconsin - Environmental Excellence

- 2024 AGC Build Wisconsin - Technology & Innovation

- 2025 AIA Wisconsin Design Award - Sustainable Design